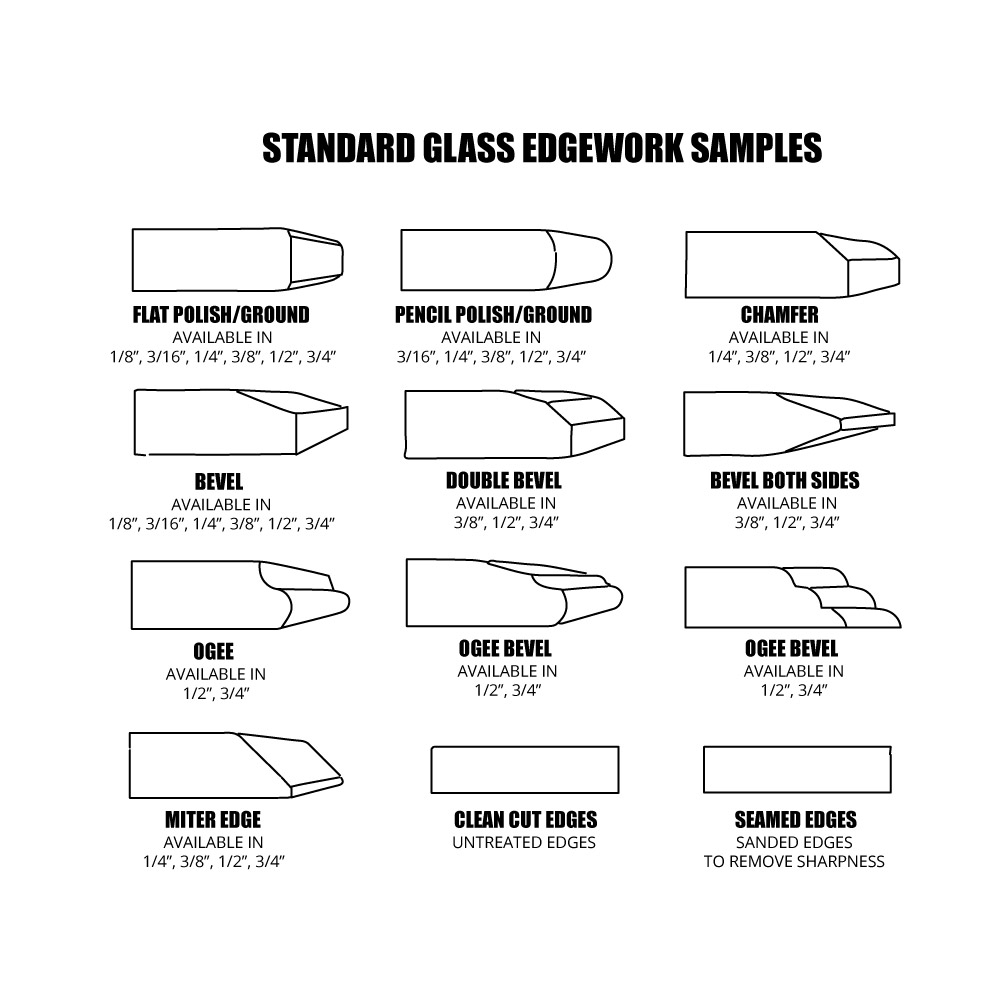

When glass is cut it leaves a razor sharp edge on the top and bottom of the glass. Obviously a razor sharp edge is quite undesirable in a finished product. A Cutting Edge Glass and Mirror, Inc. offers a range of custom glass edge finishes to meet your design requirements.

Along with the edges we also are able to customize corners in various finishes. We enable our clients to have full reign over the creative process. Offering a plethora of unique glass customization options.

We happily work with commercial interior designers as well. Below you’ll find both photos and diagrams of some of the common options, we hope this will help you visualize some of your options.

Seaming

The top and bottom edges of the glass are sanded, giving it a smooth, safe edge.

Polished

Polishing gives the glass edge a finished surface. A satin polished edge produces a low luster. For glass 3/8″ and above, a high-luster edge is generally requested, making the edge almost as smooth as the top of the glass.

Flat polish

This is the most common edge finish. The edge is ground at 90 degrees to the top surface of the glass and is finished with a satin or high luster finish. A flat polish has an “arias” (45 degree surface to remove sharpness from the glass) which shouldn’t be confused with a beveled edge.

Beveled Edge

The face of the glass or mirror edge is ground off, giving it a decorative look. Most bevels are ½” or 1″. These are the most common, however, several other widths are available.

Mitered Edge

Mitering is grinding the edge of the glass or mirror at a prescribed angle, such as a 45 angle. Two 45 degree miters could be put together to produce a 90 degree mitered corner (un-mitered glass would meet in a “butted” corner).